yeah pretty much

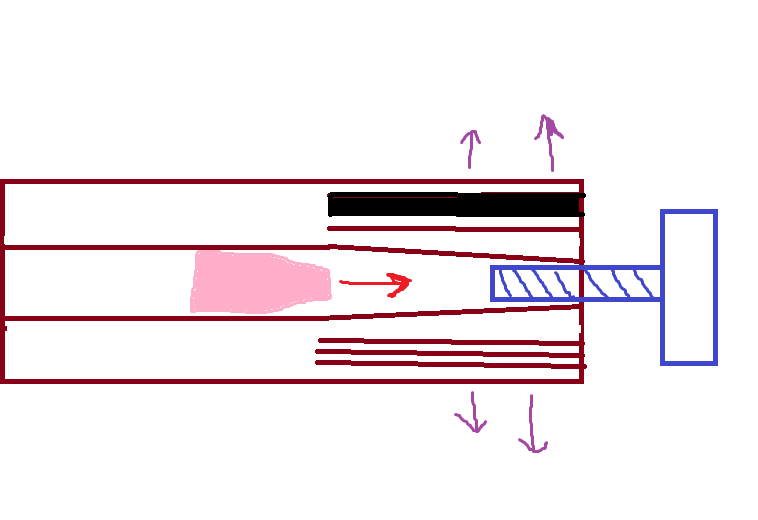

i drew a paint diagram to show it just cos paint

instead of screwing into the spindle itself, the end bolt (blue) screws into the wedge shaped bit (pink). the inside of teh axle is hollow, and tapers in slightly towards the end where the bolt lives. cos of the slots, when you tighten the end bolt the wedge is pulled towards it which splays the ends of the spindle out slightly ensuring a tighter fit on the arm, eliminating any wobble.

im sure i read back when they first promoed the design on like the merged or somewhere that the whole point of this was so the arm could slide on and off easily when the wedge was loose but would stay tight when done up.

found the article

http://themerged.com/eclat-aeon-crank/These are a 2pc 22mm crank using our new ESS (Expanding Spline System) making them incredibly strong, yet super easy to install and remove. No more taking a hammer to your cranks ever again.

if the tolerances are small enough for the arm to be a really tight fit in the first place, then the wedge is pointless anyway, and just puts additional stress on the inside of the spindle. additionally, over time i reckon the constant pressure being applied to the inside of the axle would cause it to deform slightly so that it wouldnt "spring" back as easily so youd still probs need to give it a bit of clout. who knows cos it seems the cranks didnt last long enough to put that to the test